Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

Prediction of Superplasticizers Demand in Cement Based Mortars Using Artificial Intelligence

Authors: Jyotsna Begani, Kainat Parveen, Prabhakar Sharma, Faizaan Imtiyaz, Dr. Kavita Verma

DOI Link: https://doi.org/10.22214/ijraset.2024.59444

Certificate: View Certificate

Abstract

It is anticipated that global cement based mortars production is set to achieve an annual growth rate of 5.1% for the years to come. An estimated 2 to 3% of the world\'s yearly energy use and 9 to 10% of industrial water are used by the concrete industry. It is this ever growing need of water that can be a problem for the forthcoming generations which is why nowadays superplasticizers are used highly in the construction field, these are water reducing admixtures that are capable of reducing water content hence lowering the water cement ratio without compromising the workability of end products. The study focuses on predicting the behavior concrete using machine learning approaches. The performance measure Mean Squared Error (MSE) used to assess many machine learning models. Precise prediction of superplasticizers has advantages like less wastage of water leading to conservation of it, improving the strength of concrete and reduces the need for energy intensive mixing and placement methods. This can lead to energy saving and reduced carbon footprint. The training and testing data used in his study was divided into a 70% training set and a 30 % testing set. The RMSE value of predicted and actual values had a range between 2% to 6% for testing performed on various days.

Introduction

I. INTRODUCTION

The design of concrete mixes is an important step in getting the required qualities and performance of concrete. It entails the precise selection and proportioning of ingredients like cement, water, aggregates, and admixtures to satisfy the needs of a given project.[5][8][12] Superplasticizers are the high range water reducers that are used for making high strength concrete. They also retard the setting and hardening of concrete without negatively affecting the workability of mixtures.[1] When well-dispersed cement particle suspensions are needed to enhance the flow properties of concrete, superplasticizers are employed. By adding them , the water-to-cement ratio of mortar or concrete can be lowered without impairing the mixtures workability. It makes it possible to produce high-performing and self-consolidating concrete. The primary determinant of concrete strength and durability is the water-to-cement ratio.[2] Superplasticizers significantly enhance the rheology and fluidity of newly mixed concrete. When the water-to-cement ratio drops, the strength of the concrete increases because less water is added into the hardened concrete, which improves its resistance to compression by lowering its porosity. This is done solely to keep fresh concrete more workable. [1]

Machine learning techniques have become important resources for optimizing the design of concrete compositions.[7] Large volumes of data from previous mixes may be analyzed by machine learning algorithms to forecast concrete qualities, optimize material proportions, improve quality control, and forecast long-term performance.[30][31][24] These algorithms discover patterns and links in the data, enabling more precise forecasts and better concrete mix design decisions.[27][7][29] Also, machine learning usage has the potential to improve concrete mix design's sustainability.[23][30][31] Machine learning algorithms may find ideal material combinations that minimize waste, reduce carbon footprint, and enhance the entire lifespan performance of concrete buildings by taking into account aspects like cost, availability, and environmental effect.[2][7][6]

A quantitative and statistical framework that mimics the network of neurons found in the human brain is called an artificial neural network, or ANN. It has the potential to be widely applied in engineering technologies to solve extremely challenging issues.[24][25][23] Recent research indicates that the neural network is also capable of effectively estimating the strength characteristics of construction materials.[24][29][12][15] Neural network models can predict many important parameters, including compressive strength and other important parameters like design mix, cement quantity, amount of recycled coarse aggregate substituted, drying shrinkage of concrete, and strength characteristics of geopolymer composite containing various sources.[14][10][8][5]However in his study we are going to predict the compressive strength of concrete taking input parameters as cement, water, blast furnace, fly ash and superplasticizer dosage for 3 days, 7 days, 14 days, 28 days, 56 days, 90 days and 100 days.[26] This study also aims at predicting the amount of superplasticizers taking input quantity as water, cement, aggregates, blast furnace, fly ash and compressive strength for 3 days, 7 days, 14 days, 28 days, 56 days and 100 days.

II. METHODOLOGY

A. Literature Review

In the research paper authored by Safaa M.A. an observation on what happens when LS or NSF based superplasticizers were added to OPC pastes. Additionally, the effectiveness of LS and NSF water-reducing agents in PPC-based mortar mixes were formulated using varying ratios of LS and SNF-based superplasticizers. In this investigation, the ANN model was found to be suitable for assessing the properties of mortar mixes' compressive strength and workability. The paper recorded by Joaquin Abellan-Gracia and their team suggested a two-layered neural network-based technique for predicting the CS of concrete that contains SCMs and/or RCA. K-fold cross-validation was used to keep the model from overfitting to the training set of data. Paper penned by Saumya Srivastva provided an insight on how machine learning tools are used for the prediction of various properties of concrete and quantities used.

B. Data Collection

The 1030 observations and 9 variables that make up the dataset used in this study were acquired from Kaggle. The dataset includes concrete compressive strength (in MPa), age (in days), fly ash, blast furnace slag, water, superplasticizer, coarse aggregate, and fine aggregate quantitative measurements. The objective is to forecast the compressive strength of concrete and the quantity of superplasticizers used by analyzing the relationship between these variables.

C. Experimental Program

The dataset obtained from the source was in raw form and was varied according to the number of days on which the tests for compressive strength were performed. The values were separated and then using the MATLAB software a neural network is first created with the desired number of hidden layers, number of iteration and other properties for which the data is to be feed forwarded and back propagated into the network for its training, the parameters like cement, water, fine aggregate, coarse aggregate, blast furnace, fly ash along with the superplasticizer dosage are provided as an input while the compressive strength is provided as an output for pattern recognition and training of the neural network. The regression or R values in the form of graphs are obtained after the training ,one must ensure that ideal R value is 1, however in practical situations it may not be possible to get the same, therefore it should be brought as close to 1 as possible to ensure the network is properly trained. After the training part of the network add the remaining 30% data for the testing part. The ‘sim’ function is used to simulate the network created before to make the new predictions. After the predictions are made the mean squared error is found between the predicted value and actual value and then the root mean squared error is also calculated. The root mean squared error is a measure of how accurately can our neural network predict the desired quantity.

name of network =feedforward(no of neurons);

%The above line of code is for creating a network where the name of the network lets say is ‘net’ and no of neurons can be decided accordingly for hit and trial. Let's say it is 14 .

name of network.trainParam.epochs=1000;

% no of iterations to be performed for training the network.

name of network.trainParam.lr=0.01;

% learning rate of the parameters for training the network.

[name of network, tr]=train(name of network, input,output);

%training the network named net.

predictions= sim(name of network, inn);

%simulating the network and making predictions for the same network.

mse= mean ((predictions - target).^2);

%find the mean squared error.

rmse=sqrt(mse);

%find the root mean squared error between the predicted and actual values.

disp([‘Root Mean Squared Error:’ , num2str(rmse)];

%display the root mean squared error.

plot (target, predictions, ‘bo’);

%plot the predicted and target data in form of the graph

xlabel(‘target’);

%setting the x axis for the target variable

y label(‘predictions’);

%setting the y axis for predicted variable.

title(‘target vs predictions’);

%provide the title for the graph

IV. DISCUSSION

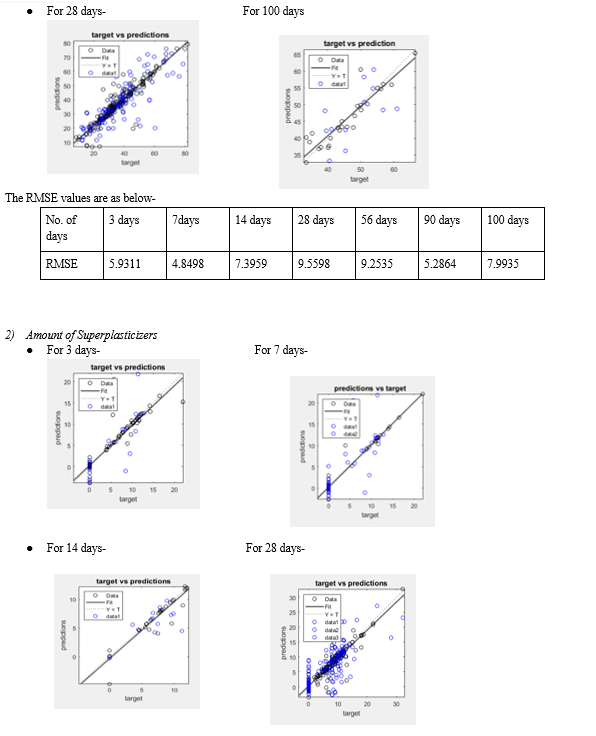

The current study suggests an approach based on neural networks with generally one hidden layer for predicting both the superplasticizers and the compressive strength of the concrete, however certain exceptions with more than one hidden layer were also made depending on the dataset available. For the training if the dataset available is large then multiple rounds of training were performed until the error in training, validation and testing data’s R value has a value near to 1. The highest RMSE value permitted was up to 10%. The graph obtained for the ‘prediction vs target’ value has four types of line in it. The gray line represents the line of best fit which implies the ideal value of data. The line of best fit which relates the dependent and independent variables with each other. For the ideal training processes the data point must lie on the line of best fit after successful training completion.The dotted line indicates the value where predicted and target value both move equally to form a straight line. The black dot represents the trained set of data , more the distance of these dots from the gray line less will be the R value and poor will be the training of the neural network. The blue dots represent the predicted set of data that are forecasted by the ANN and using these values and the targeted value the RMSE value is calculated.

References

[1] Safaa M.A. et al. ’s Effect of superplasticizers on the hydration kinetic and mechanical properties of Portland cement pastes. [2] Manikandan P ,Et Al.’s A Neural Network-Based Prediction of Superplasticizers Effect on the Workability and Compressive Characteristics of Portland Pozzolana Cement-Based Mortars. [3] Jaiswal A.N, Et Al.’s Development of high-performance concrete using ultrafine fly ash. [4] Garcia J’s ANN approach to evaluate the effects of supplementary cementitious materials on the compressive strength of recycled aggregate concrete. [5] Ngoc San , Siga S. Marundrury, Thong M. Pham,Emad Pournasiri, Feng Shi’s Effect of grounded blast furnace slag and rice husk ash on performance of ultra-high-performance concrete (UHPC) subjected to impact loading. [6] Zheng Z, Et Al.’s Numerical investigation and ANN-based prediction on compressive strength and size effect using the concrete mesoscale concretization model. [7] Shrivastava s , et al’s Prediction of concrete’s compressive strength using machine learning algorithms. [8] R. Kurad et al.’s Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete, 2017. [9] R. Somna et al.’s Effect of ground bagasse ash on mechanical and durability properties of recycled aggregate concrete, Mater. Des., 2012. [10] O. Çakir’s Experimental analysis of properties of recycled coarse aggregate (RCA) concrete with mineral additives, Constr. Build. Mater., 2014. [11] W.H. Kwan et al.’s Influence of the amount of recycled coarse aggregate in concrete design and durability properties, Constr. Build. Mater., 2012. [12] P.-M. Zhan et al.’s Strength, microstructure and nanomechanical properties of recycled aggregate concrete containing waste glass powder and steel slag powder, J. Clean. Prod., 2022. [13] K. Kapoor et al’s Durability of self-compacting concrete made with recycled concrete aggregates and mineral admixtures, Constr. Build. Mater., 2016. [14] M. Malešev et al.’s Recycled concrete as aggregate for structural concrete production Sustainability, 2010. [15] R.S. Padhi et al.’s Influence of incorporation of rice husk ash and coarse recycled concrete aggregates on properties of concrete, Constr. Build. Mater., 2018. [16] M.L. Berndt’s Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate, Constr. Build. Mater., 2009. [17] N. Arabi et al.’s Valorization of recycled materials in development of self-compacting concrete: mixing recycled concrete aggregates – Windshield waste glass aggregates, Constr. Build. Mater., 2019. [18] L.A. Qureshi et al’s Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete, Constr. Build. Mater., 2020. [19] J. Xie et al.’s Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate, Compos. B Eng., 2019. [20] Y.A. Fawzy’s Impact of recycled gravel obtained from low or medium concrete grade on concrete properties, HBRC J., 2018. [21] V. Afroughsabet et al.’s Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete, Compos. Struct., 2017. [22] F.U.A. Shaikh’s Mechanical properties of recycled aggregate concrete containing ternary blended cementitious materials, Int. J. Sustain. Built Environ., 2017. [23] Duan Z. et al’s Using artificial neural networks for predicting the elastic modulus of recycled aggregate, Constr. Build. Mater., 2013. [24] Bilim C’s et al.’s Predicting the compressive strength of ground granulated blast furnace slag concrete using artificial neural network, Adv. in Eng. soft., 2009. [25] Janib R’s et al.’ s Predicting concrete strength through packing density using machine learning model, Eng. App. of Art. Int., 2023. [26] D.C. Feng et al.’s Machine learning-based compressive strength prediction for concrete: an adaptive boosting approach, Construct. Build. Mater., 2020. [27] H. Salehi et al., Emerging artificial intelligence methods in structural engineering Eng. Struct., 2018) [28] R. Siddique et al.’s Prediction of compressive strength of self-compacting concrete containing bottom ash using artificial neural networks, Adv. Eng. Softw., 2011. [29] M. Uysal et al.’s Estimation of compressive strength of self compacting concrete containing polypropylene fiber and mineral additives exposed to high temperature using artificial neural network, Constr. Build. Mater., 2012. [30] A.T.A.Dantas et al.’s Prediction of compressive strength of concrete containing construction and demolition waste using artificial neural networks, Constr. Build. Mater., 2013. [31] J. Bai et al.’s Using neural networks to predict workability of concrete, Adv Eng Softw, 2003. [32] I. Yeh’s Modeling of strength of high-performance concrete using artificial neural networks Cem Concr Res, 1998.

Copyright

Copyright © 2024 Jyotsna Begani, Kainat Parveen, Prabhakar Sharma, Faizaan Imtiyaz, Dr. Kavita Verma. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59444

Publish Date : 2024-03-26

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online